A lot of pellet guns come with integrated sound suppressors, one of the cheapest and most popular pellet guns on Amazon does not. The pop of the expanding air at the muzzle isn’t enough for any hearing damage without a silencer, but it could annoy some close neighbors.

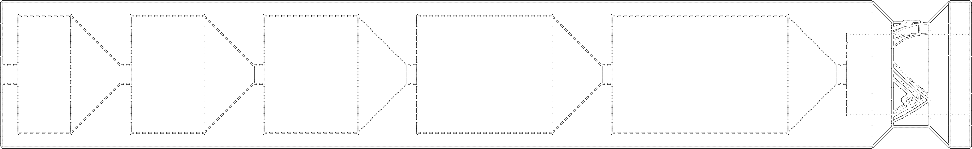

I decided to 3D print my own out of ABS filament. I looked at pictures of the insides of different silencers and came up with my own design. It had to be able to mate to the pellet gun’s barrel in some way, fit inside my printer’s print volume, and be designed in a way that would let the baffles print without supports. This is what I came up with in SolidWorks:

The baffles are sloped at 45 degrees to print without supports and the expansion chambers decrease in volume in the direction of fire. The silencer is permanently epoxied to the barrel.

I tested the sound of each suppressed shot and saw a slight drop in sound pressure levels from the unsuppressed shots. The shots are noticeably quieter!

Some places I want to improve this design:

- Quick-detach barrel mount

- Off-axis pellet channel to improve scope visibility

- Optimized baffle spacing (ideally using CFD software)

Email me at wilsonlima5@gmail.com if you have any questions, suggestions, or would like me to send you the files you need to print your own.